PLANARGROW GRAPHENE CVD SYSTEMS

|

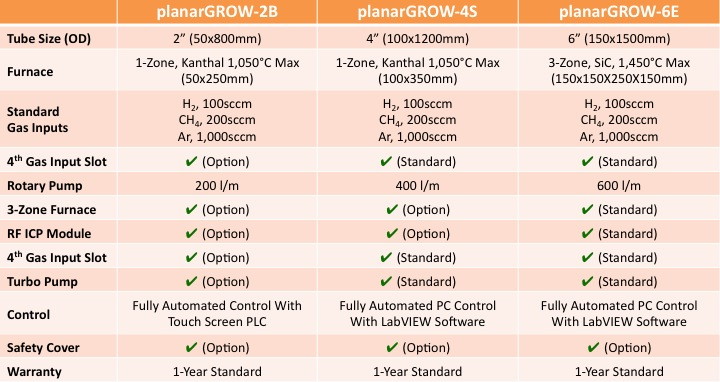

The planarGROW series of thermal CVD systems for graphene (and CNT growth with minor modifications) is a horizontal hot-wall reactor system. We offer three standard system configurations (planarGROW-2B, planarGROW-4S, and planarGROW-6E) as shown in the table below. However, each of these standard systems can be customized to the user's specific application requirements. A more detailed system specification for the planarGROW-4S follows the table below.

|

|

PLANARGROW-4S PRODUCT SPEC (GRAPHENE CONFIGURATION)

|

QUARTZ TUBE & FURNACE

• Tube Dimensions: ф100*1200mm • Furnace Body (WxHxD): 500x500x350 • Heater: Kanthal Wire w/ Glass Wool Molding • Maximum Temperature: 1,100°C • Thermocouple: K type, ID 6.5 mm • Heating Zone: 1-zone, ф100*350mm • Linear Motion Control Unit • Manual Furnace Door GAS SUPPLY UNIT • Three (3) Celerity TN2900 Mass Flow Controllers o Hydrogen (H2), 100sccm o Methane (CH4), 200sccm o Argon (Ar): 1,000sccm • Open Mounting Bay for Fourth (4th) MFC • ¼” Stainless Steel Tubing • Five (5) ¼” Pneumatic-Type Diaphragm Valves VACUUM & PRESSURE CONTROL UNIT • Atovac CG201 Convection Gauge • Atovac CG2000 Convection Gauge Controller • Atovac ACM200, 10 Torr Capacitance Manometer • Atovac ATV1000 Motor-Geared Throttle Valve • GPC3000 Pressure & Flow Controller • WSAutoma W2V40 Rotary Pump (400 liter/min) SYSTEM CONTROL UNIT • MS Windows XP Pro Embedded PC o Intel 3.0Ghz Core2Duo, 2GB Memory • PLC Module with National Inst. LabVIEW Interface • Samsung E1920R 19” LCD Monitor SAFETY & COOLING • Water Cooled End Flanges • Buzzer Alarm & System Error Display • Interlock System DIMENSIONS & UTILITY REQUIREMENTS • Footprint: 1.75m (W) x 1.60m (H) x 0.75m (D) • Weight: ~200kg • Power: 220V, 50/60Hz, 3Φ, 4-wire, 30A • Air: 4-5kgf/cm2, ¼” tube • Water: 2-3kgf/cm2, ½” tube |

Example of a planarGROW-4S with a 3-zone Furnace

Fully Automated PC Control with LabVIEW Front End

Example of a planarGROW-2S With Turbopump

|

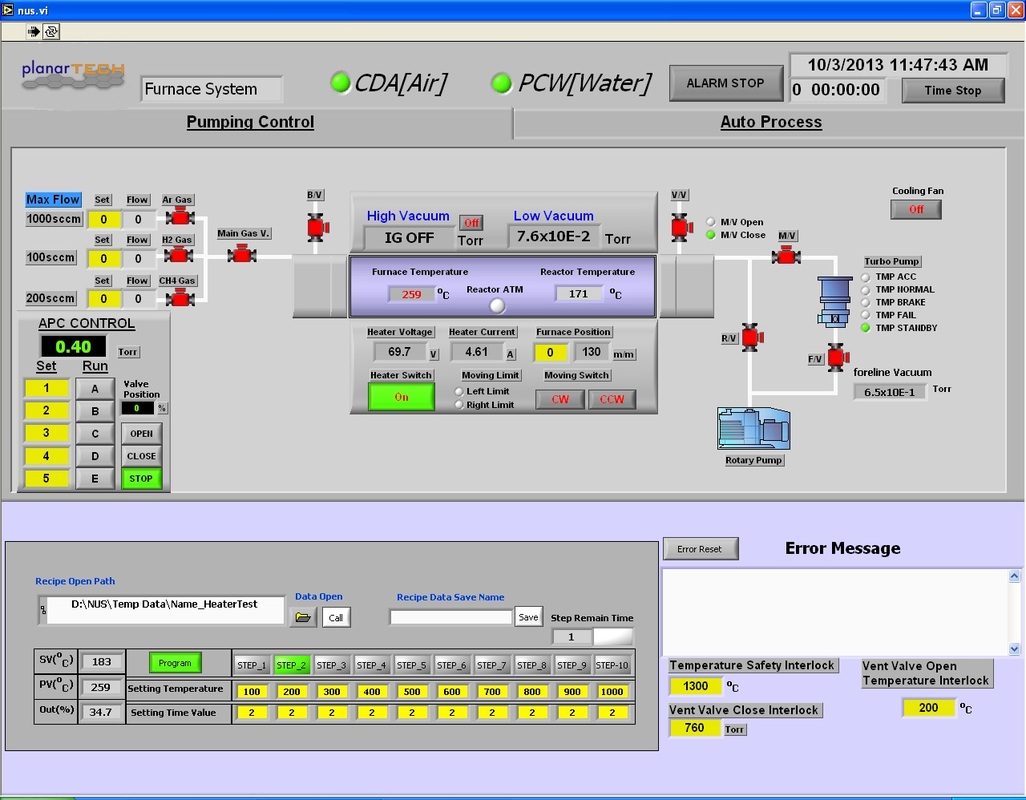

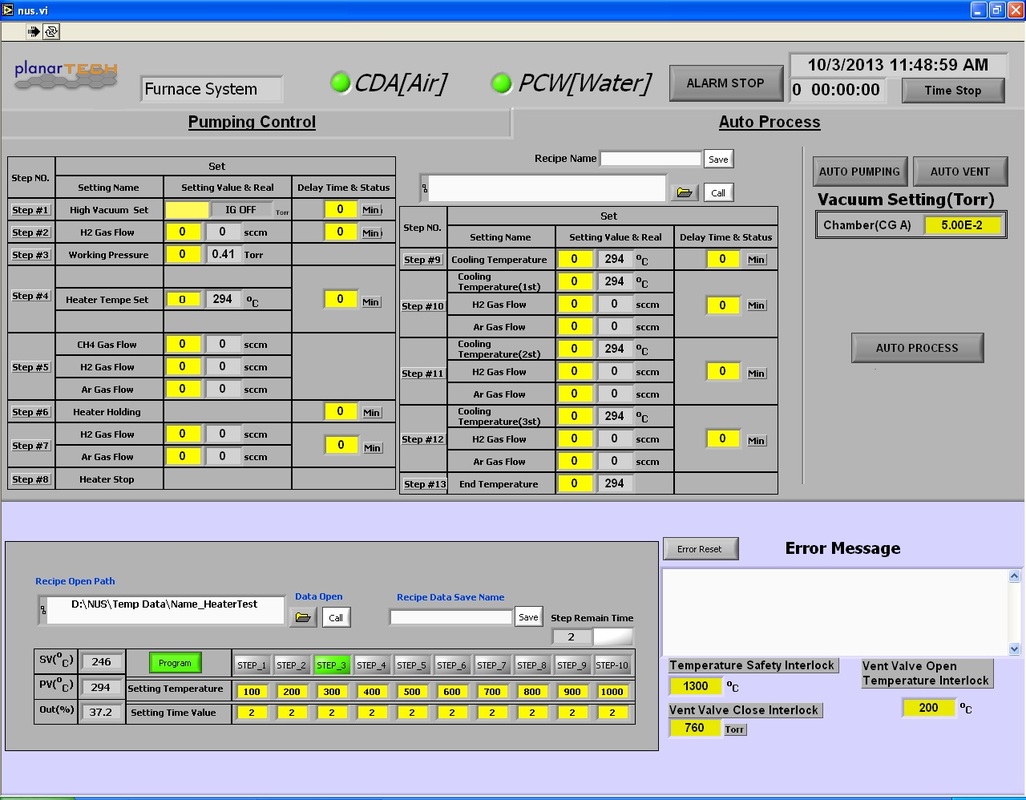

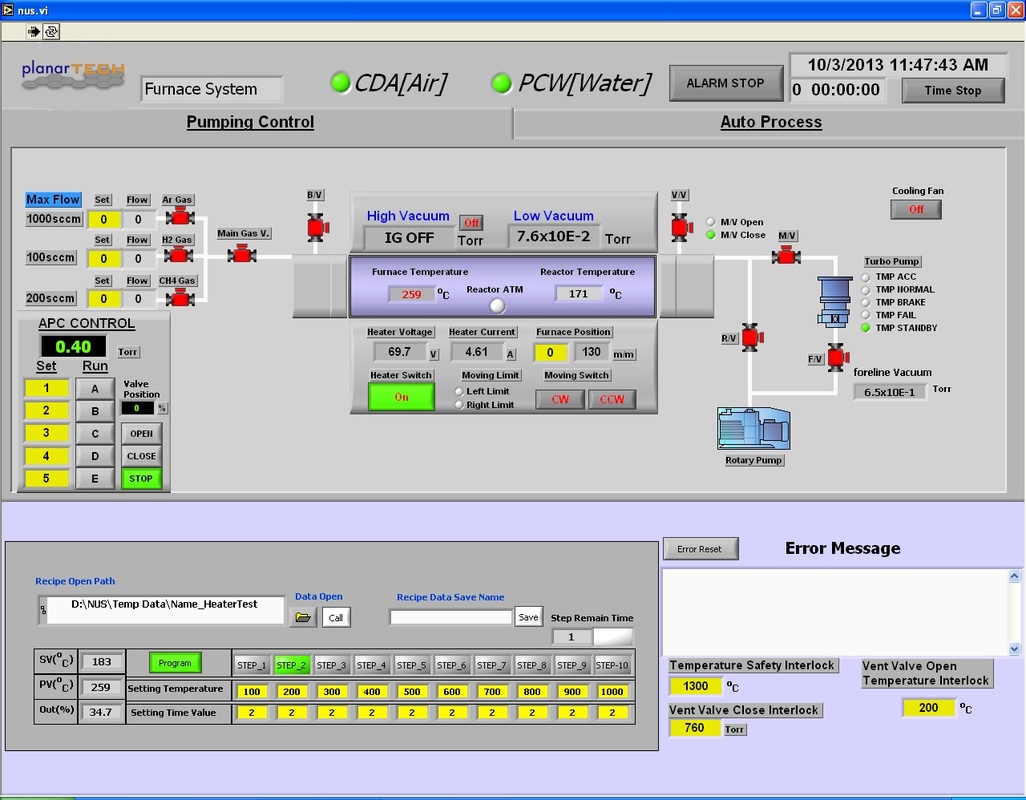

PLANARGROW-4S SOFTWARE INTERFACE

One of the key benefits of the planarGROW product line is its ease of use via a fully functional Graphical User Interface (GUI) built around National Instruments LabVIEW software. This GUI allows full control of each system parameter, allows the user to load and save custom growth recipes, and enables “1-click” unattended operation via an auto process feature. The images below are screenshots of the GUI for a planarGROW-2S system with a high-temperature furnace and a turbopump, which are offered as options. (Click images to enlarge.)

GRAPHENE SYNTHESIS WITH THE PLANARGROW-4S

The planarGROW-4S is equipped with a 4” (100mm) outer diameter primary quartz tube that can accommodate large sized Cu foils. During synthesis, however, planarTECH recommends using one or more smaller 1.5” or 2” outer diameter quartz tubes as carriers for the samples. This has two benefits: 1) Cu decoration will mainly affect these smaller tubes, prolonging the useful life of the primary quartz tube; and 2) it allows for growth of multiple samples in parallel. Even when using these smaller tube sizes, it is possible to grow samples on Cu foils up to 100x200mm. The images below-left shows a finished 100x100mm sample next to a 1.5” carrier quartz tube, and the image below-right shows a view of the carrier tube inside the furnace from the right flange viewport.

Finished 100x100mm Graphene Sample

|

A View of a Carrier Tube via the Viewport

|

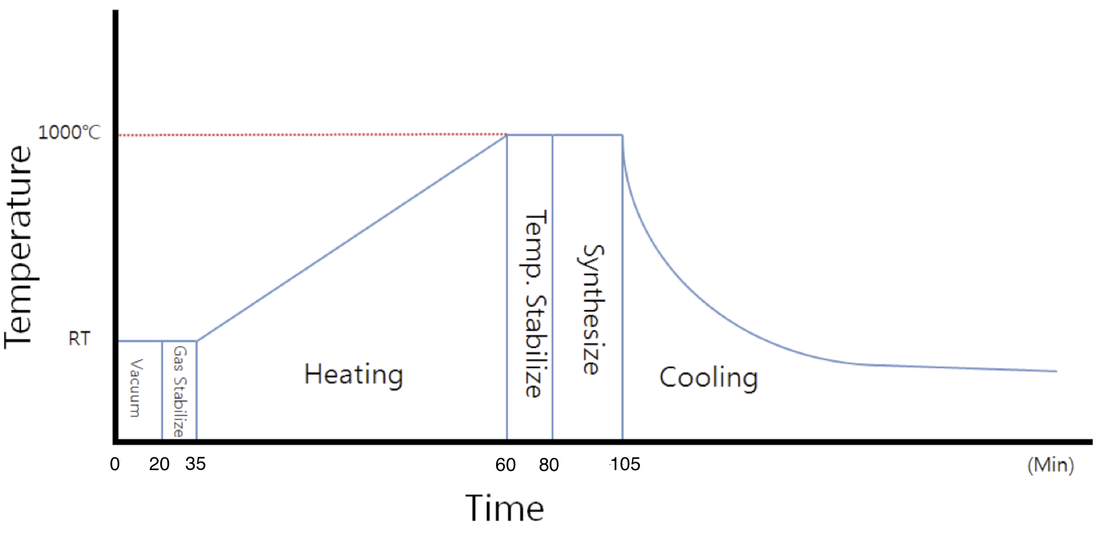

The figure below-left shows a typical operation cycle for graphene synthesis on a system with a standard Kanthal wire furnace. Fast run capability allows samples to be loaded at room temperature, processed and removed from the furnace after ~120 minutes. However, the actual time per run will be dependent on the recipe for graphene growth. (For example, growing large domain single crystals takes much more time than growing full coverage monolayer graphene with a smaller domain size.

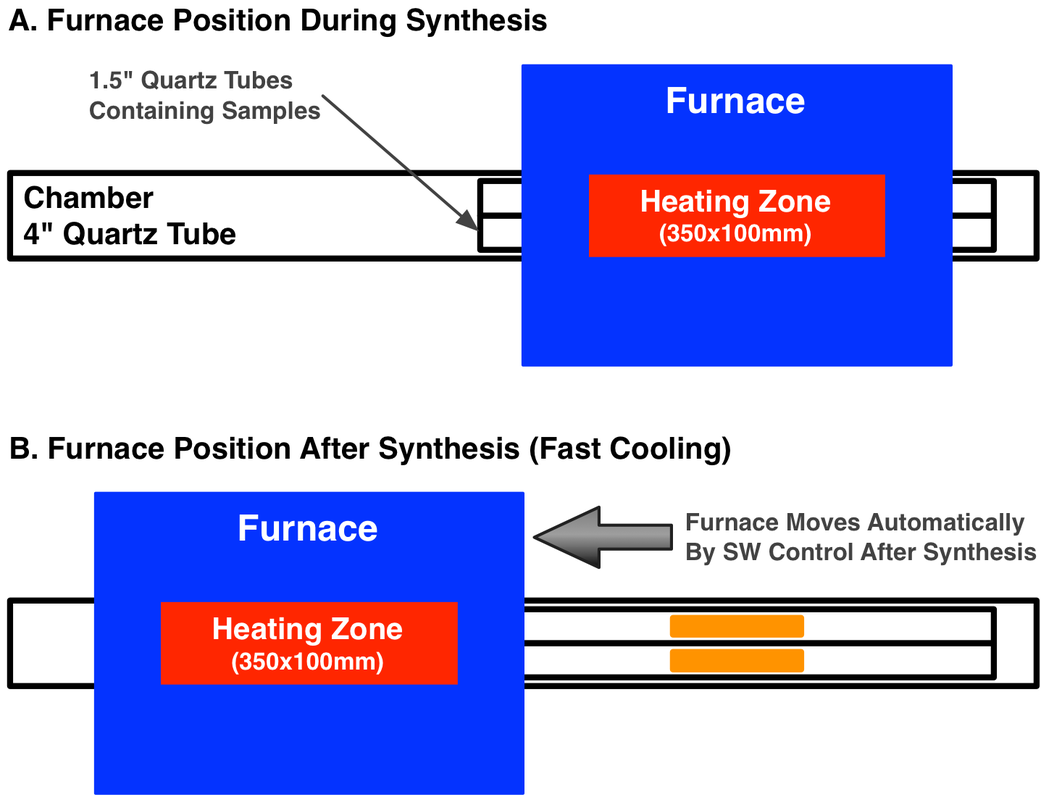

The default heater configuration of the planarGROW-4S is a moveable 1-zone furnace, which is controlled by the software interface. The software can be programmed such that after graphene synthesis has finished the furnace will be switched off and moved away from the samples to enable fast cooling operation as shown in the image below-right.

The default heater configuration of the planarGROW-4S is a moveable 1-zone furnace, which is controlled by the software interface. The software can be programmed such that after graphene synthesis has finished the furnace will be switched off and moved away from the samples to enable fast cooling operation as shown in the image below-right.

A Typical Operation Cycle for Graphene Synthesis

|

Fast Cooling Operation Method

|

GRAPHENE & CNT SYNTHESIS REFERENCES

With over 15 years of use for carbon nanotube (CNT) and graphene synthesis, the planarGROW product line has been used to synthesize the graphene with experimental results published in leading academic journals. For a partial list, please view our References page. In addition, please view our Installations page for photo galleries of recent customer installation sites.

STANDARD WARRANTY

Each planarGROW system is delivered with a standard warranty that covers all parts – excluding quartzware and O-rings – for one (1) year from the date of installation at the customer site. Any defects in materials or workmanship during the warranty period will remedied by repair or replacement free of charge.

ON-SITE SETUP & TRAINING

After delivery, planarTECH or its local representative/distributor will send a technical team to the customer site to perform proper installation of the planarGROW system, verification of its operation and a quality check. This installation process typically takes one to two days to complete. Prior to on-site setup, the customer must complete necessary preparations, such as providing the proper electrical, water and gas hookups. planarTECH will provide the customer with a complete checklist after receiving an order. After successful setup of the planarGROW system, planarTECH or its local representative/distributor will provide on-site training in the operation and use of the system.

SHIPPING POLICY

planarTECH ships each planarGROW system to the customer site by Incoterms CIP (Carriage & Insurance Paid) air freight direct from its factory in Korea. The cost of shipping is included in the base price.

VUI LÒNG LIÊN HỆ HOTLINE: 098 918 2955 / 090 265 9944

CTY NAM Ý

Tin tức khác

- Bỏ túi 5 mẹo dọn dẹp để làm mới thiết kế website (25-08-2017)

- Website chuẩn SEO - những tiêu chí cơ bản (18-08-2017)

- dây nano bán dẫn là gì? (10-02-2017)

- Plasma tăng cường lắng đọng hơi hóa học (PECVD) là gì? (10-02-2017)

- THIẾT BỊ CVD GRAPHENE USA (10-02-2017)

- Một lớp CVD Graphene Màng PET cho các ứng dụng R & D - Graphenea Tổng quan về sản phẩm (10-02-2017)

- CVD Graphene - Tạo Graphene Bằng PP ngưng tụ hóa học Chemical Vapour Deposition (CVD) (10-02-2017)

- Tiềm năng ứng dụng của công nghệ nano (10-02-2017)

Đang online:

Đang online:  Hôm nay:

Hôm nay:  Tuần:

Tuần:  Tháng:

Tháng: